#Staff Column

2023.07.05

The Resurgence of Packaging

Columnist | Introducing the columns written by member of Amorepacific Group

Green Packaging

Part 2. The Resurgence of Packaging

Part 2. The Resurgence of Packaging

Columnist

Lee Chankyu

Amorepacific Package Research Team

Amorepacific Package Research Team

In our prior discourse on the subject of packaging, we highlighted the critical role packaging plays in preserving a product's integrity and amplifying its appeal. A well-conceived packaging solution is not merely functional; it also provides a delightful

‘unboxing’ experience and leaves a lasting impression on consumers. Moreover, we are now at a juncture in which packaging bears a significant ‘societal and environmental responsibility.’ We will delve into the discussion of packaging that garners the

approval of customers and society alike, instead of being solely aesthetically pleasing.

A Modern World Devoid of Plastic?

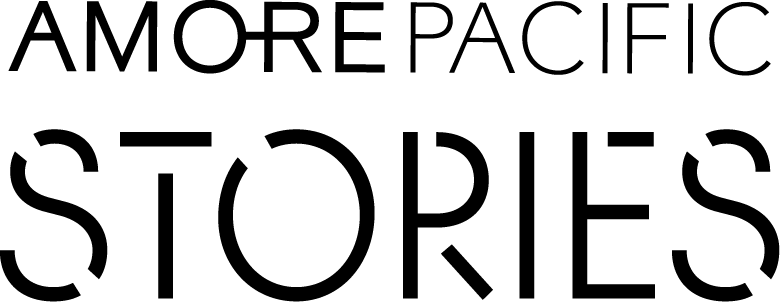

Envision a modern society stripped of all plastic; it would likely mirror a world similar to the one a century ago before plastic came into existence. It would bear semblance to the 19th century when the mainstays were materials such as glass, ceramics,

wood, paper, and metal. Of late, there is a marked uptick in interest in products evoking a sense of nostalgia. Despite certain inconveniences, such products are hitting the market without plastic, or bearing vintage-inspired packaging, thus offering

a refreshing alternative.

▲Source: www.cosmeticsandskin.com, https://americanhistory.si.edu/

< COTY Cosmetics and Oral Care Products from a Century Ago >

▲Source: www.cosmeticsandskin.com, https://americanhistory.si.edu/

< COTY Cosmetics and Oral Care Products from a Century Ago >

If we transition to a world without plastic, our everyday consumer goods would undergo significant transformation. Food items, particularly, would present substantial challenges. The sourcing of ingredients would need to be local, and even if long-term

preservation methods such as canning or salting were employed, a trade-off on freshness would be inescapable. Household and cosmetic goods would face similar hurdles too. We would have to relinquish some of the convenience and preservation benefits

that we take for granted. An even more daunting issue is that it would be difficult to expect a diverse range of formula that requires specifically-designed containers.

The Engine that Propels Urban Existence

T he affluence characterizing modern urban life can be largely attributed to the advent of electricity and the wide-scale use of plastic. Yet, plastic has garnered a negative perception in two significant respects. The first involves accelerating the

exhaustion of finite petroleum resources, and the second pertains to the detrimental environmental impact that arises from the manufacture and disposal of plastic. The environmental implications of plastic directly influence ecosystems and indirectly

impact the climate through carbon emissions. Although resource depletion was previously a more dominant concern, the current focus is primarily on climatic issues.

Over the past half-century, the consumption of plastic and petroleum resources has skyrocketed. However, with the discovery of new oil reserves and the advancement of technology, the prevailing sentiment seems to be that the environmental consequences are more urgent than resource depletion. This shift in perspective is evident in the swift expansion of regulatory policies. Spearheaded by Europe, regulations such as the ‘carbon border tax’ and ‘compulsory use of recycled plastic’ have been introduced to curtail the impact of plastic. This movement is now gaining momentum in other nations, including the United States and South Korea, albeit with varying degrees of urgency and execution.

We draw a parallel between modern urban existence and a cartwheel, powered by resources. The size of the population is commensurate with the size of the wheel, and the rate of urbanization can be likened to the speed of the wheel's rotation. As urbanization escalates and the population increases, the wheel enlarges, and the consumption of plastic rises in tandem. Consequently, the wheel leaves behind a trail of remnants that exert a lasting impact on the environment.

Over the past half-century, the consumption of plastic and petroleum resources has skyrocketed. However, with the discovery of new oil reserves and the advancement of technology, the prevailing sentiment seems to be that the environmental consequences are more urgent than resource depletion. This shift in perspective is evident in the swift expansion of regulatory policies. Spearheaded by Europe, regulations such as the ‘carbon border tax’ and ‘compulsory use of recycled plastic’ have been introduced to curtail the impact of plastic. This movement is now gaining momentum in other nations, including the United States and South Korea, albeit with varying degrees of urgency and execution.

We draw a parallel between modern urban existence and a cartwheel, powered by resources. The size of the population is commensurate with the size of the wheel, and the rate of urbanization can be likened to the speed of the wheel's rotation. As urbanization escalates and the population increases, the wheel enlarges, and the consumption of plastic rises in tandem. Consequently, the wheel leaves behind a trail of remnants that exert a lasting impact on the environment.

< The Surge in Plastic Consumption and Its Consequences >

< The Surge in Plastic Consumption and Its Consequences >

Countries experiencing peak levels of urbanization are reinforcing regulations that limit plastic use and such measures may decelerate the growth rate of plastic consumption. However, escaping the global proliferation of plastic usage appears improbable

due to the persistent population expansion and urban development in burgeoning regions.

Bioplastics Derived from Nature

One notable strategy to mitigate these plastic-related challenges involves the employment of bio-based plastics. Prior to the advent of petroleum as a dominant material for plastic production, humans had been harnessing natural polymers like wood and

plant matter for ages. Technological advancements allowed us to refine these natural substances for various uses. From the 19th through to the 20th century, we chemically processed materials of natural origin, yielding a range of resins including natural

rubber and cellulose. Nonetheless, as it became increasingly difficult to address the escalating demand, the exploration for petroleum-based materials began.

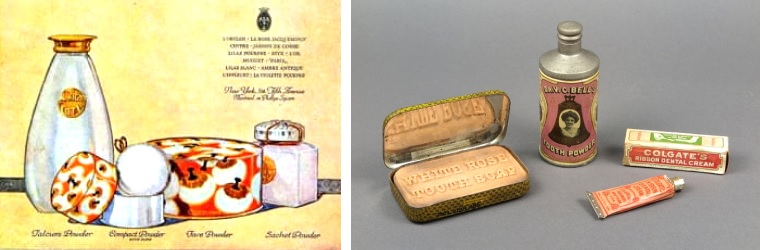

In light of the escalating issues related to petroleum-based substances, interest has rekindled in materials derived from nature. These materials form the basis for what we call bioplastics, with Polylactic Acid (PLA) being a prominent example. The production involves utilizing residual natural substances derived from plants like sugarcane. PLA has gained considerable traction in food packaging and is making headway in the cosmetic packaging sector. Beyond PLA, there are endeavors to produce plastics like Polyhydroxyalkanoates (PHA) using microorganisms. The industry that is focused on replacing traditional materials with these bio-based alternatives is known as the white biotech industry. It serves as a catalyst for alleviating resource-depletion concerns through the use of renewable resources and has a role in reducing CO2 emissions.

In light of the escalating issues related to petroleum-based substances, interest has rekindled in materials derived from nature. These materials form the basis for what we call bioplastics, with Polylactic Acid (PLA) being a prominent example. The production involves utilizing residual natural substances derived from plants like sugarcane. PLA has gained considerable traction in food packaging and is making headway in the cosmetic packaging sector. Beyond PLA, there are endeavors to produce plastics like Polyhydroxyalkanoates (PHA) using microorganisms. The industry that is focused on replacing traditional materials with these bio-based alternatives is known as the white biotech industry. It serves as a catalyst for alleviating resource-depletion concerns through the use of renewable resources and has a role in reducing CO2 emissions.

▲Source: www.natureworksllc.com, www.plasticstoday.com

< Harnessing Renewable Plant Resources for Plastic Production >

▲Source: www.natureworksllc.com, www.plasticstoday.com

< Harnessing Renewable Plant Resources for Plastic Production >

That being said, they cannot satisfy all market demands. Non-food resources must be employed, and constraints arise in terms of the available land for production, yield volume, and efficiency. Nonetheless, consistent expansions in production are occurring,

leading to projections that bio-based materials could account for approximately 25% of total plastic production in the future.

A Return to Nature: Biodegradable Plastic Packaging

The non-degradable characteristic of plastics has transformed them into a pivotal environmental concern, contaminating land and endangering aquatic life. In response to this escalating issue, we've seen the advent of biodegradable products designed for

more efficient decomposition after use. This process resembles the way wood, left to the elements, disintegrates with microbial activity. It's important to note, however, that these biodegradable plastics often fall short in terms of durability — a

necessary trade-off for their eco-friendly decomposition properties.

Biodegradable plastics are divided into two types: those that naturally decompose in terrestrial or aquatic environments, much like ordinary natural matter, and those requiring artificially induced high-humidity, high-temperature conditions for composting. The previously mentioned Polylactic Acid (PLA), for instance, is a type of bioplastic that decomposes under composting conditions. Naturally decomposable materials typically involve products manufactured using natural components such as wood, starch, and rice husks. These are mixed with a variety of other elements to create packaging suitable for a range of applications.

Biodegradable plastics are divided into two types: those that naturally decompose in terrestrial or aquatic environments, much like ordinary natural matter, and those requiring artificially induced high-humidity, high-temperature conditions for composting. The previously mentioned Polylactic Acid (PLA), for instance, is a type of bioplastic that decomposes under composting conditions. Naturally decomposable materials typically involve products manufactured using natural components such as wood, starch, and rice husks. These are mixed with a variety of other elements to create packaging suitable for a range of applications.

▲Source: bioverpackung-nissha.com

< Sulapac Packaging, Utilizing Wood and Other Elements >

▲Source: bioverpackung-nissha.com

< Sulapac Packaging, Utilizing Wood and Other Elements >

It might seem instinctive to prefer materials that decompose naturally. However, it takes between 10 and 100 years for even wood to decompose. Thus, quick composting of plastic might be a more advantageous strategy. Instead of presuming that naturally

decomposable materials are always superior, factors such as the level of moisture exposure during use, the need for prolonged usage, and the intended application should be evaluated when choosing the material.

The Recycled Materials

While plastics can be designed to decompose efficiently, they can never fully replicate natural soil. Even fast composting processes require a minimum of six months, making comprehensive waste treatment a significant challenge. Therefore, to minimize

incineration and landfill, recycling these materials is a necessity.

Ideal scenarios would see products being used for extended periods or repurposed, but the common practice is to finely shred used packaging and recycle it into new raw material. This practice produces what is known as Post Consumer Recycled (PCR) material. Utilizing PCR materials can notably reduce the consumption of fresh raw materials derived from petroleum. For the production of superior-quality recycled materials, it's crucial to gather and recycle plastics with similar properties. Hence, from the development phase itself, emphasis should be placed on products made from singular materials or those conducive to recycling — as previously discussed under the ‘uni material’ concept.

Many individuals, not well-versed in the intricacies of recycled products, often operate under the misconception that using recycled materials is a cheaper alternative. However, the reality is that high-quality recycled materials generally command a higher price point than virgin materials — in some cases, the costs can even double. The reasons behind this include the complexities associated with automating the recycling process at a significant scale, as well as the considerable expenses incurred to ensure superior product quality. Therefore, when manufacturing PCR products, it's essential to foster comprehensive dialogue concerning quality disparities and potential cost escalations. Maintaining sustainability is fundamental to ensuring a steady supply of trustworthy raw materials and exercising consistent quality management.

For industries such as cosmetics and household product packaging — where a high demand exists for bright and transparent products — the integration of recycled materials has historically presented a considerable challenge. In the initial stages of incorporating recycled materials, the focus predominantly lay on the use of Post Industrial Recycled (PIR) plastics. Although these are high-grade materials repurposed from industrial waste, physical PCR plastics now dominate the field.

Chemical PCR products, on the other hand, are produced by decomposing recycled materials down to the raw material level, thus achieving quality on par with virgin materials. This has sparked an increase in the number of companies intensifying their investment and developmental efforts toward chemical PCR production, partly driven by regulatory shifts. The European Union, for instance, is progressively expanding regulations concerning the application across member states. As a result, not only are products utilizing PCR plastic becoming increasingly prevalent, but those using PCR glass materials are also gaining momentum. Similarly, in Korea, legal mandates stipulating up to 30% of PCR PET production are in place, signifying anticipated expansion beyond cosmetics and household goods into the realm of food packaging.

Ideal scenarios would see products being used for extended periods or repurposed, but the common practice is to finely shred used packaging and recycle it into new raw material. This practice produces what is known as Post Consumer Recycled (PCR) material. Utilizing PCR materials can notably reduce the consumption of fresh raw materials derived from petroleum. For the production of superior-quality recycled materials, it's crucial to gather and recycle plastics with similar properties. Hence, from the development phase itself, emphasis should be placed on products made from singular materials or those conducive to recycling — as previously discussed under the ‘uni material’ concept.

Many individuals, not well-versed in the intricacies of recycled products, often operate under the misconception that using recycled materials is a cheaper alternative. However, the reality is that high-quality recycled materials generally command a higher price point than virgin materials — in some cases, the costs can even double. The reasons behind this include the complexities associated with automating the recycling process at a significant scale, as well as the considerable expenses incurred to ensure superior product quality. Therefore, when manufacturing PCR products, it's essential to foster comprehensive dialogue concerning quality disparities and potential cost escalations. Maintaining sustainability is fundamental to ensuring a steady supply of trustworthy raw materials and exercising consistent quality management.

For industries such as cosmetics and household product packaging — where a high demand exists for bright and transparent products — the integration of recycled materials has historically presented a considerable challenge. In the initial stages of incorporating recycled materials, the focus predominantly lay on the use of Post Industrial Recycled (PIR) plastics. Although these are high-grade materials repurposed from industrial waste, physical PCR plastics now dominate the field.

Chemical PCR products, on the other hand, are produced by decomposing recycled materials down to the raw material level, thus achieving quality on par with virgin materials. This has sparked an increase in the number of companies intensifying their investment and developmental efforts toward chemical PCR production, partly driven by regulatory shifts. The European Union, for instance, is progressively expanding regulations concerning the application across member states. As a result, not only are products utilizing PCR plastic becoming increasingly prevalent, but those using PCR glass materials are also gaining momentum. Similarly, in Korea, legal mandates stipulating up to 30% of PCR PET production are in place, signifying anticipated expansion beyond cosmetics and household goods into the realm of food packaging.

▲Source: www.premiumbeautynews.com, www.verescence.com

< Cosmetic Containers Incorporating PCR Plastic and PCR Glass >

▲Source: www.premiumbeautynews.com, www.verescence.com

< Cosmetic Containers Incorporating PCR Plastic and PCR Glass >

In our previous discussion, we delved into instances of reduced plastic usage, and in this segment, we explored the role of alternative resources in addressing the issues associated with petroleum-derived materials. While strides toward resource circulation

have been initiated, we are still in the nascent stages of this movement. At this juncture, it's predominantly the eco-conscious trailblazers in the industry that are making concerted efforts to broaden the use of such resources. However, we are confident

that, within a few short years, an increasing number of companies will seamlessly incorporate eco-friendly products into their operations. The prospect of a world free of plastic waste, a world where resource circulation is the standard protocol in

every stage of product creation and disposal, is gradually becoming a more tangible reality.

-

Like

3 -

Recommend

0 -

Thumbs up

0 -

Supporting

0 -

Want follow-up article

0

Array ( )